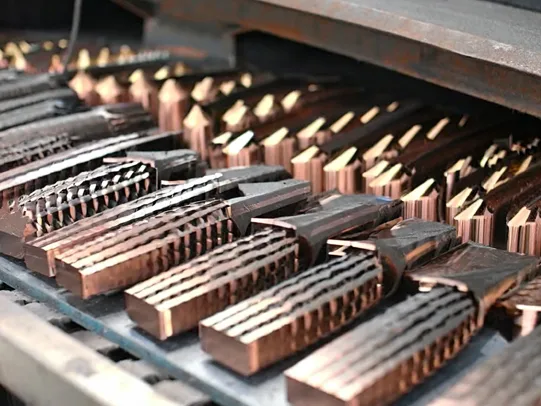

Carbon Graphite Automotive Brushes Manufacturing

We are an industry leader in the carbon graphite aftermarket brush industry, as well as a supplier to major OEM manufacturers.

Each of our brushes can be custom-designed to your specific requirements. We develop our own proprietary grades and manufacture each product in-house, so we will work closely with you to find the right brush grade or develop new grades to optimize the performance of your generator, alternator or starter.

We don’t simply machine a product to a different specification; we are able to alter the base materials and physical properties of our products to make them ideal for your needs.

ENVIRONMENT, OPERATING CONDITIONS & APPLICATIONS

STABILITY AT HIGH TEMPERATURES

Our proprietary mix of carbon graphite is able to withstand extreme temperatures, which allows our brushes to be used in a variety of harsh environments while still maintaining performance and increasing your equipment’s uptime.

LOW FRICTION / WEAR

The self-lubricating properties of our brushes will greatly reduce the amount of friction and wear during operation, significantly reducing maintenance time, replacement and equipment damage.

SELF-LUBRICATING

Our automotive brushes are self-lubricating, meaning that a separate lubricant (e.g., oil) is not required, which allows them to be used in both dry-running and sanitary environments.

OXIDATION-RESISTANT

Our proprietary mix of carbon graphite resists chemical degradation of the surface material, allowing our brushes to be used in harsh environments while maintaining performance.

KEY END PRODUCTS

Our brushes are used in the motors of a variety of end products as listed below. Remember that we custom-design our products to fit your needs, so please contact us if you have a need outside of those below and we’ll work with you to find a solution.

- Automobiles

- Trucks

- Buses

- Construction Vehicles & Equipment

- Vintage Vehicles

- Motorcycles

HOW CAN WE HELP YOU ?

Carbon Graphite Automotive Brushes Details

Working Temperature

- Minimum

- Runs in cryogenic temperatures (no true minimum value)

- Maximum

- Carbon/Graphite up to 700 F

- Electrographite up to 900 F

- Electrographite with inorganic additives up to 1150 F

- Other oxidation inhibitors (impregnants) up to 1200 F

- In inert/neutral environments

- Carbon/Graphite up to 1600 F

- Electrographite up to 5000 F

Key Markets

Our brushes are used across a wide range of different markets, including:

- Automotive

- Power Generation

- Construction

- Transportation

- Mining

Product Material

Average Oxidation & Chemical Resistance

- Carbon grades are resistant to most chemicals

Spring Pressure Range

- Application dependent

Amp per sq inch

- 75 – 150 A/in2

How carbon graphite will make your products & parts superior

Explore our latest resources

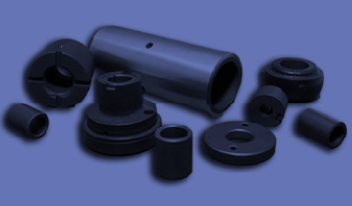

Carbon Graphite Mechanical Seal Types

Rotating equipment often requires a dynamic mechanical seal to create a seal between a rotating shaft and a stationary body and prevent the escape of process fluid(s) including liquid and/or gas. They can also be used in mixer seals to prevent fugitive ambient particulates from entering a contained vessel being being mixed such as a pharmaceutical reaction…

Why Bearings Fail and How to Prevent It

All bearings have a fixed life expectancy. Some are replaced because of normal wear or spalling, and others need replacing because of premature wear or failure. An unexpected failure can cause damage to equipment, downtime, costly replacement, and possibly even injury. And, even before they fail, the premature wear is likely to have effects on performance …

Carbon Graphite Conductivity & Expansion

When deciding on the materials for carbon graphite components or parts, it all starts with a thorough review of the application which includes the components’ form/function/fit and property identifying the “must haves” and the “nice to haves” and melding these with a design for manufacturability. There are three important physical characteristics …