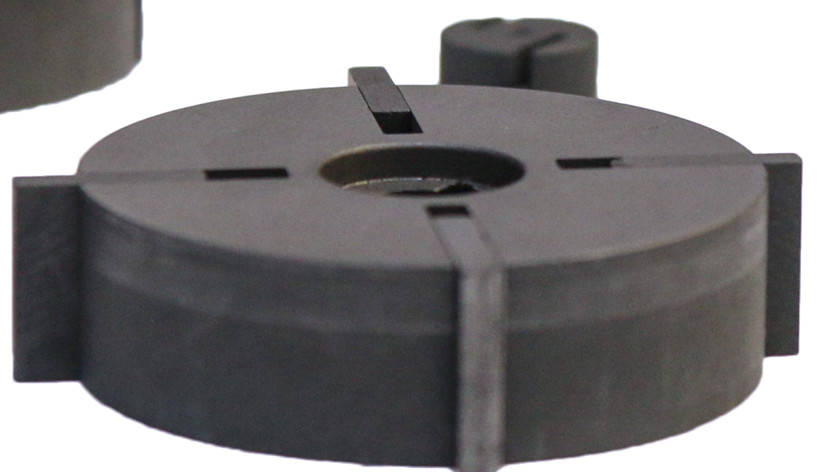

CARBON GRAPHITE VANES & ROTORS MANUFACTURING

St. Marys Carbon manufactures Rotors & Vanes from superior carbon graphite grades for a variety of applications. Our rotors & vanes are made from specialized, proprietary materials that are required for many of the unique environments in which rotors & vanes are used. All of our rotors & vanes, from the blending of raw materials to the finished product, are made in-house by our specialized craftsmen.

If you require a customized solution, we can manufacture our carbon graphite rotors and vanes to your specific requirements. We develop our own proprietary grades and manufacture each product in-house, so we will work closely with you to create a carbon graphite product that is right for you.

ENVIRONMENT, OPERATING CONDITIONS & APPLICATIONS

DRY-RUNNING / OIL-LESS

Greatly reduces failure rates and allows for use in sanitary environments due to its self-lubricating properties.

HIGH TEMPERATURE STABILITY

Maintains high strength and runs effectively without failure at high temperatures.

LOW FRICTION / WEAR

Resists wear and reduces friction as it is chemically inert, oxidation-resistant and self-lubricating.

KEY END PRODUCTS

Our rotors & vanes are used in a wide range of end products as listed below. Remember that we custom-design our products to fit your needs, so please contact us if you have a need outside of those below and we’ll work with you to find a solution.

- Air Pumps & Compressors

- Beverage Pumps

- Chemical Pumps

- Space Heaters

- Fuel Pumps

- Medical Pumps

- Vacuum Pumps

- De-icing Units

HOW CAN WE HELP YOU ?

CARBON GRAPHITE VANES & ROTORS DETAILS

Working Temperature

- Minimum

- Runs in cryogenic temperatures (no true minimum value)

- Maximum

- Carbon/Graphite up to 700 F

- Electrographite up to 900 F

- Electrographite with inorganic additives up to 1150 F

- Other oxidation inhibitors (impregnants) up to 1200 F

- In inert/neutral environments

- Carbon/Graphite up to 1600 F

- Electrographite up to 5000 F

Key Markets

You can find our carbon graphite rotors and vanes used across a wide range of different markets, including:

- Aerospace

- Chemical

- Environmental

- Food & Beverage

- Medical

- Plastics

- Printing & Paper

Product Material

Average Oxidation & Chemical Resistance

- Carbon grades are resistant to most chemicals

Spring Pressure Range

- Application dependent

Moisture level

- We offer grades that will work in both low and high-humidity environments

Vacuum pressure Level (Vanes)

- Application dependent

CARBON GRAPHITE GRADE

| Grade | Density(lbs./ft.3) | Flexural Strength (psi) | Compressive Strength (psi) | Coefficient of Thermal Expansion (u/°F) | Temp Limit Neutral (°F) | Temp Limit Oxidizing (°F) | Scleroscope Hardness | Applications |

|---|---|---|---|---|---|---|---|---|

| 404 | 112.32 | 10,000 | 28,000 | 2.30 | 1,600 | 700 | 90 | Rotors |

| 378 | 114.19 | 11,000 | 32,000 | 2.80 | 500 | 500 | 95 | Rotors |

| 22S | 117.07 | 10,000 | 28,000 | 4.13 | 500 | 500 | 90 | Rotors |

| 429 | 108.58 | 9,000 | 28,000 | 2.50 | 1,600 | 600 | 110 | Vanes |

| 270 | 107.95 | 10,000 | 25,000 | 2.30 | 1,600 | 700 | 80 | Vanes |

| 394 | 114.19 | 12,000 | 33,000 | 2.50 | 1,600 | 650 | 90 | Vanes |

How carbon graphite will make your products & parts superior

Vanes & Rotors Data Sheet

Explore our latest resources

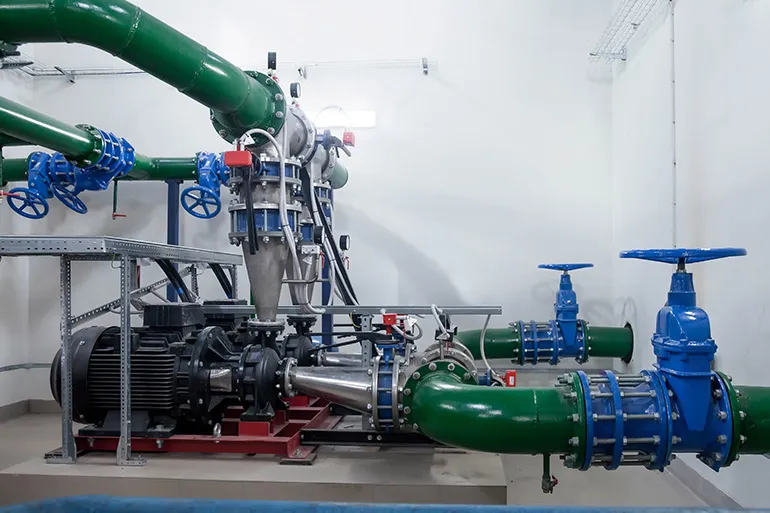

INNOVATION IN BEVERAGE PRODUCTION

In the field of beverage production, efficiency, hygiene, and product quality are paramount. A key component in maintaining these standards is the beverage pump, a critical piece of equipment for the transfer of liquids during production. The performance and reliability of these pumps are crucial, as they directly influence…

CARBON GRAPHITE PRODUCTS FOR THE AEROSPACE INDUSTRY

In the aerospace industry, the selection of materials plays a crucial role in determining the efficiency, reliability, and overall success of various applications. Among the diverse range of materials employed, carbon graphite has emerged as a particularly valuable resource, especially in the fabrication of critical components such…

CARBON GRAPHITE ANTI ICING SYSTEMS

As winter sets in, the challenges posed by ice and snow become a big concern for various sectors. De-icing systems play an essential role in mitigating these challenges, ensuring safety and operational continuity in harsh weather conditions. Central to the effectiveness of these de-icing systems are their core components…